22 |

AUDITORIUM THEATRE 2014-2015

| OCTOBER 3 - OCTOBER 29

On the

Road

by Hannah Rubin

When American Ballet Theatre is in residence at Lincoln

Center’s Metropolitan Opera House for its annual 8-week

run, it can be hard to remember that the com- pany has

no theater of its own to call home. Despite its roster of

talent and lavish productions, ABT remains a touring

company at heart, packing up and hitting the road every

few months to take its ballets all over the world. In the

last year or two, the company has toured from Oman to

Japan, with stops in between, not to mention frequent

visits to Los Angeles, Washington DC and other U.S. cit-

ies. This September will take the company for the first

time to Australia. But putting elaborate story ballets on

the road re- quires more than packing some tutus. The

sheer logistics of an ABT tour can rival Ringling Brothers.

As dancers, stage managers and wardrobe supervisors

explain, touring has its own special hazards, as well as

undeniable rewards.

For James Whitehill, the company’s Production Direc-

tor, step one is moving the sets. For ABT’s recent Japan

tour, where the company presented The Nutcracker and

Manon as well as a mixed bill, the ballets’ scenery had to

be shipped 45 days in advance via ocean container in four

forty-foot high cubes. However, no matter how tightly the

cubes are packed, not everything can fit. For each in- ter-

national trip, a day or two in advance of the company’s

arrival, Whitehill also sends an air freight shipment often

weighing as much as 7000 pounds. It has essential items

like the dancers’ rehearsal wear and extra pointe shoes,

as well as critical production equipment that may not be

readily available at the destination, like lighting gels.

Whitehill travels with a team to mount the ballets.

Personnel includes a technical director, a lighting director,

three stage managers, three car- penters, three electri-

cians, two prop handlers, four wardrobe people and two

wig-and-makeup people. Depending on their destination,

the crew may be augmented locally, or the presenter may

bring in more personnel from farther afield. “The Middle

East doesn’t have a big local theatrical community, and

there’s not an experi- enced workforce to bring back-

stage and put to work,” says Whitehill. “When we were in

Oman, the sultan had just built the opera house, and they

hired a production coordinator from London who had

Royal Opera House experi- ence. In order to find enough

crew for back- stage, he had to bring people in from Aus-

tralia, London and Belgium.”

Building the sets can present challenges even when

experienced crew members are available lo- cally. “We

have a great team of translators in Japan,” Whitehill says.

“There may sometimes be tension between our crew and

the Japanese crew heads. The translators get caught in

the middle—they have a hard time translating what’s said

in such a way as to avoid offending either side.”

Moving costumes and shoes for 90 dancers around

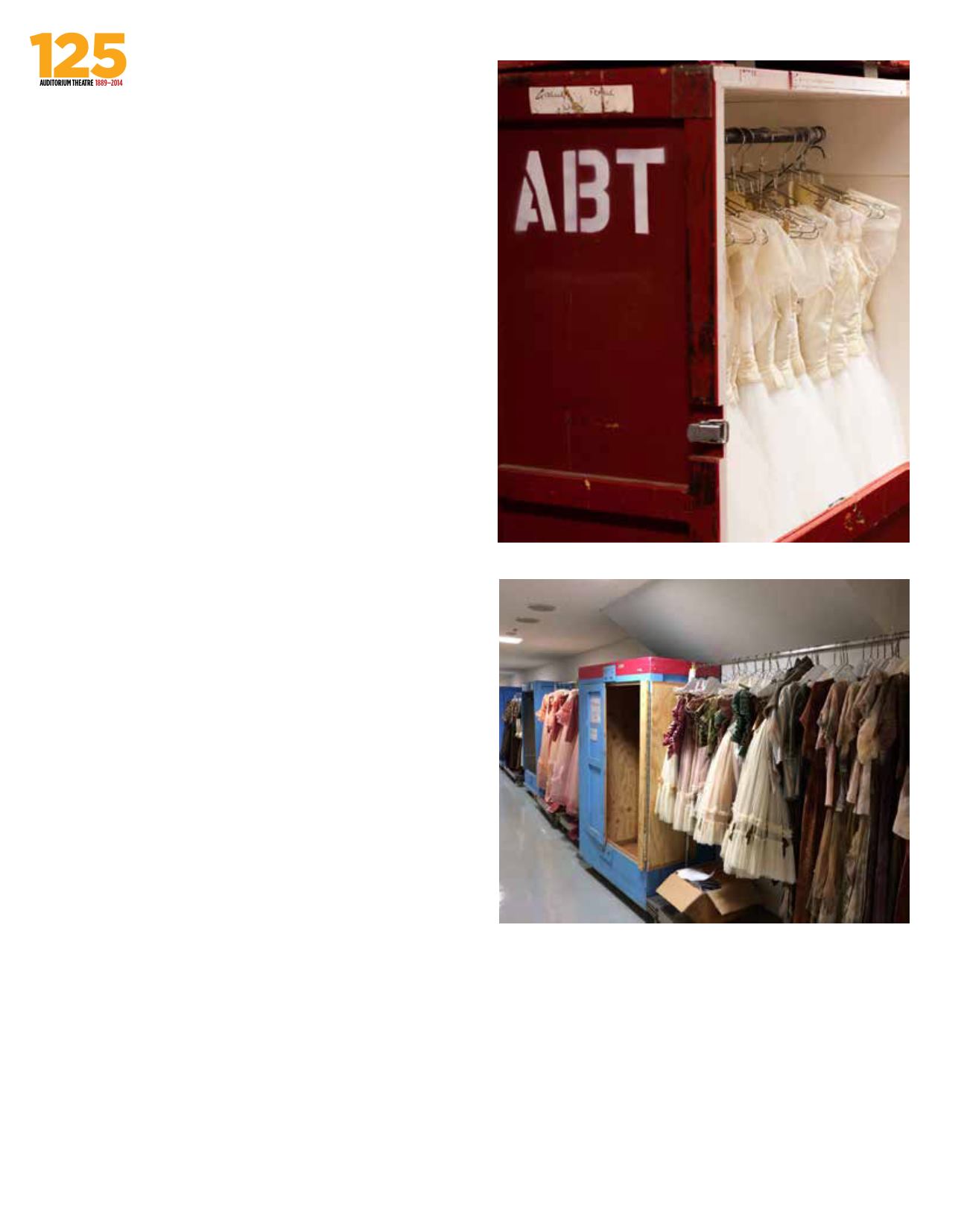

Wilis costumes from Giselle on the move. Photo: Renata Pavam.

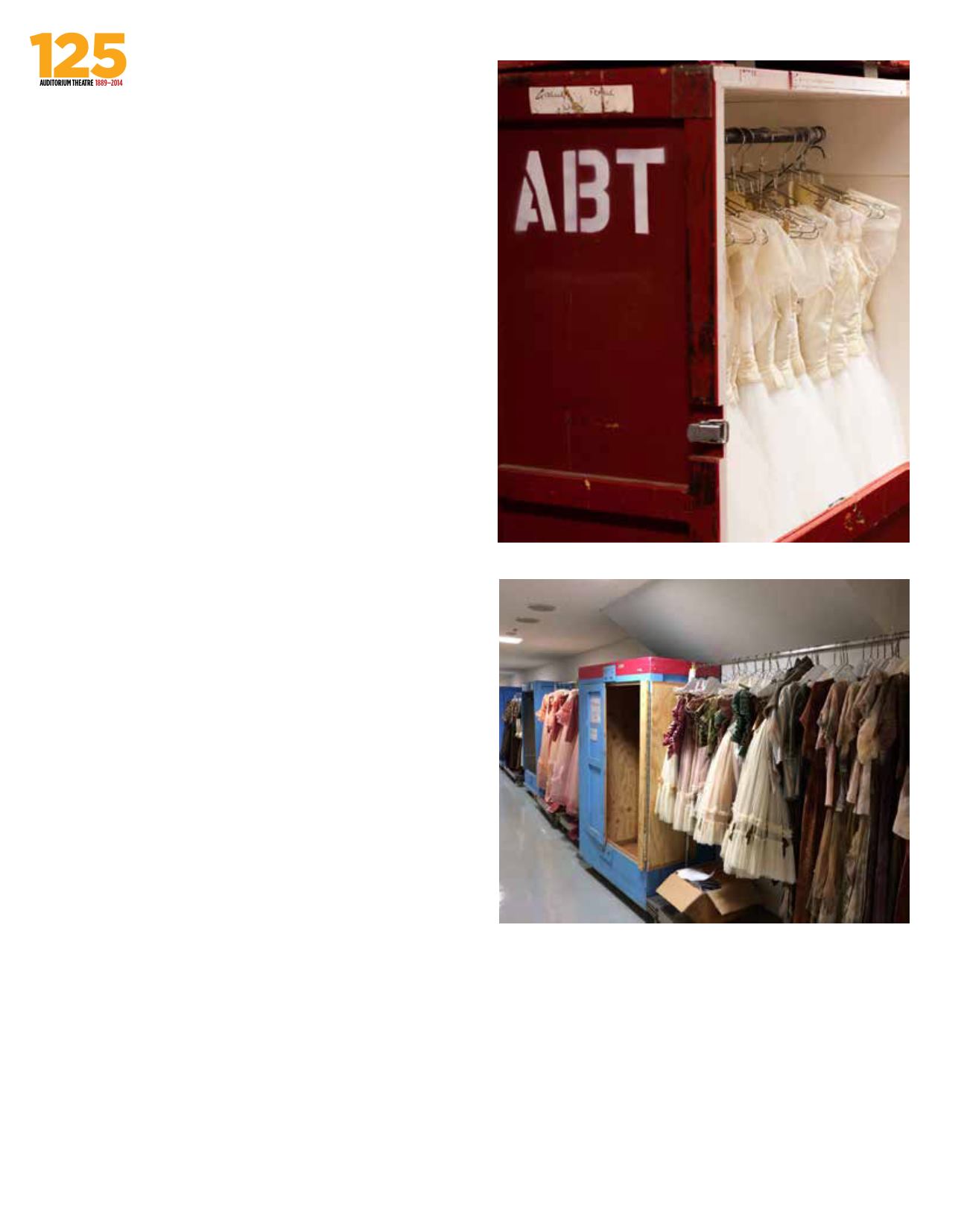

Manon costumes line the backstage hallway in Otsu, Japan.

Photo: Courtesy Japan Arts.